The proces

As much as one third of all building materials delivered to a typical construction site will end up as waste . Construction and demolition debris makes up 10 to 30% of the waste received on landfill sites. The remainder has to be incinerated. Incineration or dumping will obviously create a huge negative impact on the environment. The Netherlands aims at reducing primary resources by half in 2030. It is important to shift gears and use fewer raw materials and less energy. By using biomass and or regenerated plastics – such as being produced by CSX – a real circular approach to exploit sites, buildings and interiors will come a step closer. Contact us for more information about civil engineering.

KΞΞN ®

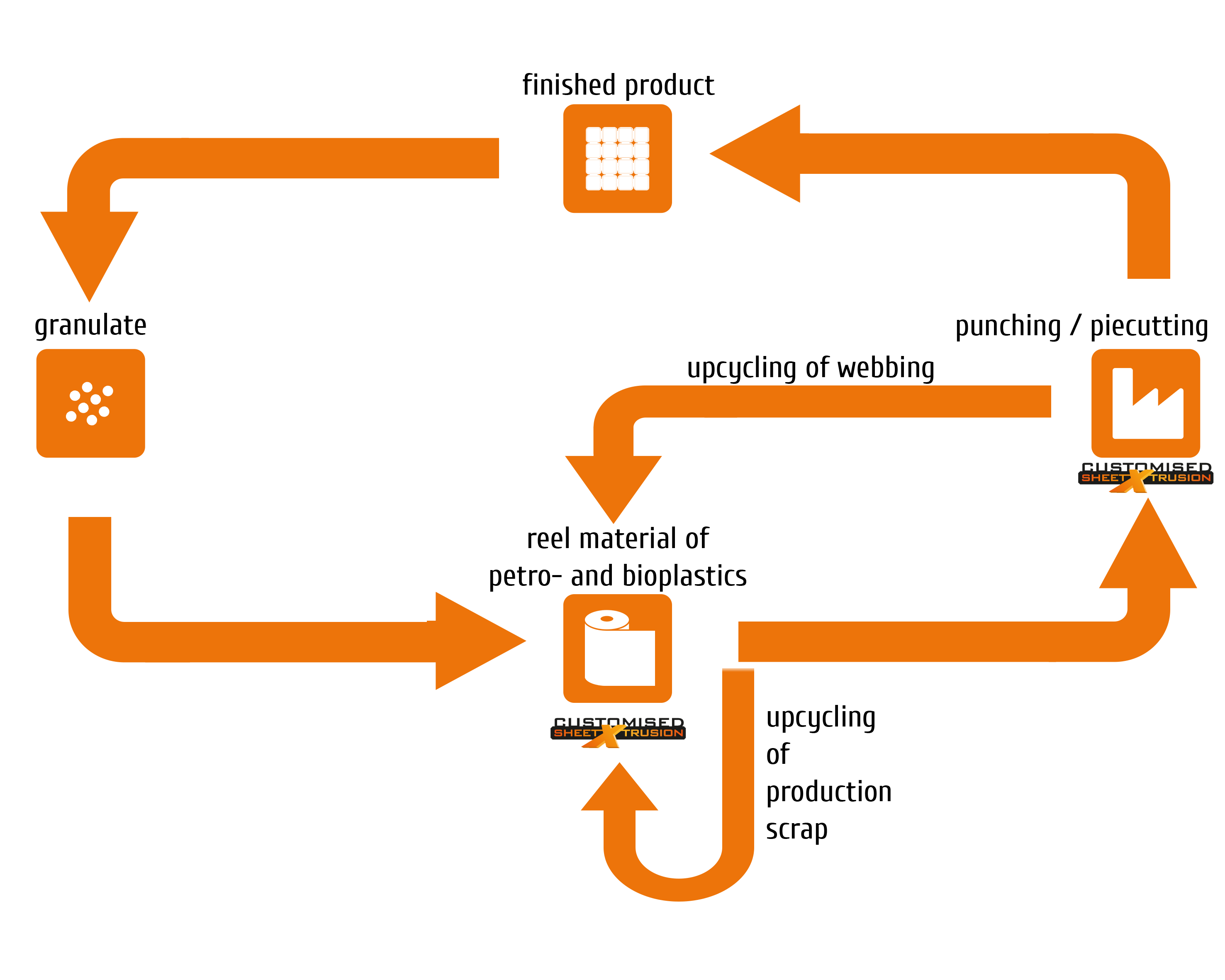

By implementation of the principle of a Circular Economy, CSX wants to become one of the leaders in Europe in developing plastic sheet materials and film.

Sustainable

CSX is not only considering existing generations, but also future generations. Due to their environmentally friendly production process CSX is aiming to produce to state of the art sustainable standards and beyond.

Clean

Environmentally friendly production processes are at the forefront of CSX. CSX strives for a system in which raw materials are fully re-deployed in a Circular Loop system.

Civil engineering: The solutions

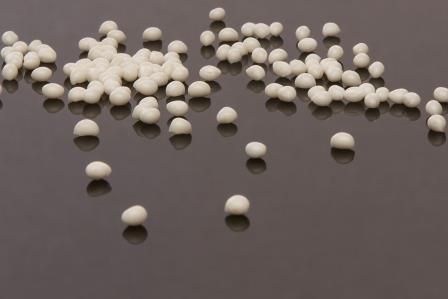

Granulate

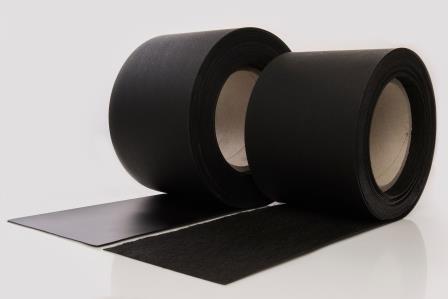

Reels & sheetmaterial